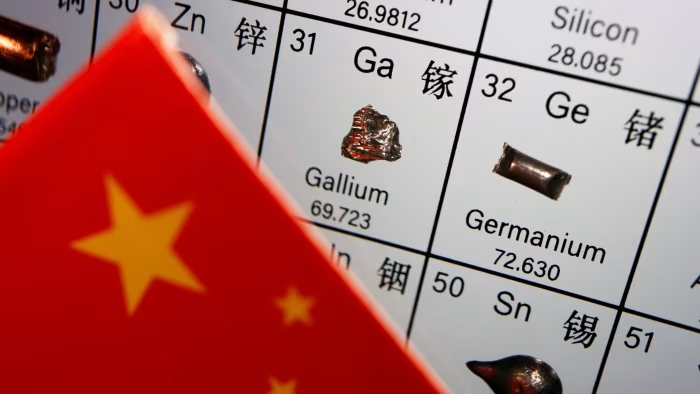

China has taken a significant step to tighten its control over rare-earth metals, adding five more metals to its export restrictions. This move expands Beijing’s regulatory grip on these critical materials, which play a crucial role across many high-tech industries worldwide.

The metals recently added to China’s export control list include holmium, erbium, thulium, europium, and ytterbium. These join seven others that China has already restricted, bringing the total number of rare-earth metals under export control to 12 out of the 17 that make up this group. Rare-earth metals, which consist of 15 lanthanides on the periodic table along with scandium and yttrium, are essential components in manufacturing everything from magnets and semiconductors to electric vehicles and defense systems.

China’s latest regulations require foreign companies to obtain special approvals from Beijing if they want to export rare-earth magnets and certain semiconductor materials containing a minimum of 0.1% heavy rare-earth metals. This policy tightens the flow of these materials in global supply chains, especially in high-tech sectors where their application is often crucial.

The restriction on heavy rare-earth metals is particularly important because these metals have unique magnetic, luminescent, and electrochemical properties that light rare-earths cannot replicate. Industries that rely heavily on precision magnets, like electronics, renewable energy, electric vehicle manufacturing, and various defense technologies, will be watching closely to understand the potential ripple effects.

By exerting more control over the export of these metals, China is reinforcing its already dominant role in the rare-earth supply market. The country is the world’s leading producer and exporter of rare-earth elements, accounting for a substantial portion of global supply. As a result, this move is likely to create tighter conditions for countries that do not have significant domestic sources or refining capabilities of these materials.

Countries across Asia, North America, and Europe, which depend on rare-earth metals for their manufacturing processes, are facing increased pressure to diversify their supply chains. This includes boosting domestic production, securing alternative sources in other countries, or investing in recycling technologies to reclaim rare-earth elements from used products.

While governments and companies have been aware of supply risks associated with rare earths for several years, recent geopolitical tensions and market disruptions have underscored the vulnerability of supply chains heavily reliant on China. These new export controls could accelerate ongoing efforts to reduce dependence on China and bring forward investments in rare-earth mining and processing outside of the country.

Semiconductor manufacturers also stand to feel the impact, as certain components now require special import approvals due to the rare-earth metal content. With semiconductors playing a foundational role in modern technology from smartphones to vehicles, additional export hurdles may affect production costs, timelines, and ultimately product availability.

The general industry faces a tightening landscape where securing the necessary materials could become more costly and time-consuming, leading to a potential slowdown or increased prices for products that incorporate these metals. Companies will need to evaluate their supply chain strategies closely and possibly increase inventories as a hedge against future disruptions.

Looking ahead, China’s strategic control over rare-earth elements serves as a reminder of the geopolitical dimensions that underpin critical material markets. This development reinforces the importance of continued innovation in material science and recycling technologies, as well as international cooperation to build resilient supply chains in an era marked by increasing resource-related competition.

The broad impact of China’s export control tightening on rare-earth metals will be felt across multiple sectors for some time. How countries and companies adapt to this new reality will shape technology development and supply chain patterns over the coming years.

This expanded regulatory stance by China marks a critical juncture for global industries that depend on rare-earth metals. It challenges stakeholders to rethink sourcing frameworks and investment priorities to ensure continued access to these indispensable materials that fuel modern technology.