California-based sports car manufacturer Czinger is poised to make a significant leap forward in its operations, with plans to commence deliveries of its highly anticipated 21C hybrid supercar later this year. The company’s success in setting lap records worldwide with the 21C has piqued the interest of both automotive and aerospace sectors, resulting in new partnerships to leverage Czinger’s cutting-edge manufacturing techniques.

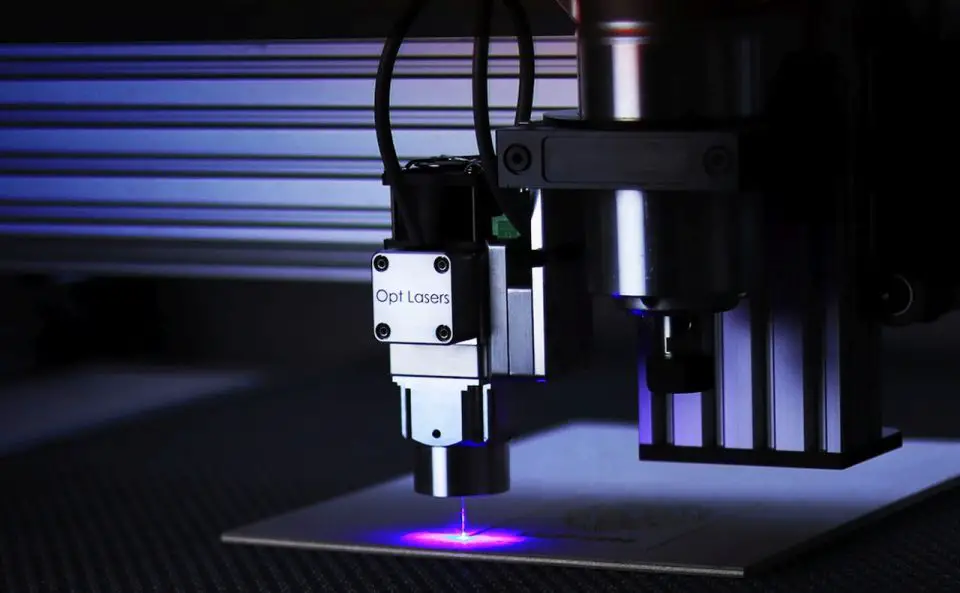

Central to the 21C’s remarkable performance is its groundbreaking construction process. Czinger employs a combination of 3D printing and additive manufacturing, employing lasers and metal dust to fashion components unattainable through conventional means. Additionally, artificial intelligence plays a pivotal role in designing components that are not only lightweight but also exceptionally robust.

The manufacturing arm of Czinger, in collaboration with its parent company, the privately-held Divergent, orchestrates the creation of the 21C supercar—a masterpiece valued at approximately $2 million. This same innovative methodology is extended to external collaborators, including automotive titans like Aston Martin and Mercedes, as well as over 30 aerospace enterprises necessitating precision-crafted parts. The latest feather in Divergent’s cap is the partnership forged with General Atomics.

During an exclusive interview founder and CEO Kevin Czinger unveiled the inner workings of the C21’s custom-made components. Here, AI takes the lead in crafting a design that fulfills all safety and durability requisites in the most compact, lightweight form, ultimately maximizing performance. Subsequently, additive manufacturing and 3D printing spring into action, churning out what Czinger affectionately terms “LEGO blocks.” A robotic marvel, aptly named the “robotic octopus,” deftly assembles these parts in a circular area, deviating from conventional assembly line methods.

Czinger elaborates, labeling their venture a multifaceted endeavor. “We are a materials company. We’re an additive manufacturing company and we’re actually an assembly company as well,” asserts COO Lukas Czinger, Kevin’s son. He gestures toward the rear of the car, where the hood unfurls to reveal a labyrinthine, almost extraterrestrial, arrangement of components constituting the rear subframe housing the engine, suspension, and an array of structural and cooling elements.

“This rear frame right here actually represents generative design, AI-driven generative design, novel aluminum alloys, 3D printing, and fixture assembly,” he expounds. Lukas Czinger highlights that this section of the vehicle accounts for around 450 patents, while the entire system boasts a staggering 650 patents.

In addition to fulfilling orders for 80 C21 supercars, Czinger and Divergent face the imperative to rapidly expand their operations. Beyond their existing facilities near Los Angeles International Airport, the company aims to establish an additional 30 facilities by the close of the decade. This ambitious undertaking will bolster their capacity to design, fabricate, and produce custom parts on a grand scale. With over $700 million in capital raised thus far, Kevin and Lukas Czinger are well-positioned to navigate this transformative phase.

Source: Yahoo Finance