Desktop Metal (NYSE: DM), a prominent player in Additive Manufacturing 2.0 technologies, has unveiled a game-changing innovation with the launch of its Reactive Safety Kit for the Production System P-1. This breakthrough technology unlocks safe, high-speed binder jet 3D printing of titanium and aluminum, marking a significant advancement in the additive manufacturing industry.

Following this announcement, Desktop Metal’s stock is experiencing a surge, currently valued at $0.835 with a notable increase of 5.28% in trading volume. The new Reactive Safety Kit by Desktop Metal, developed over two years, features ATEX-rated components and critical hardware and software updates, ensuring the highest level of safety standards. ATEX certification, a rigorous European Union directive, validates the safety of equipment for use in explosive atmospheres, further enhancing Desktop Metal’s credibility in the market.

Ric Fulop, Founder and CEO of Desktop Metal, expressed pride in the company’s ability to offer a commercial 3D printer with safety features necessary for binder jet 3D printing of titanium and aluminum. Fulop stated, “Titanium and aluminum are highly demanded materials, and we are excited to enable their 3D printing with the required safety measures. Our technology is poised to unlock new designs, delivering higher performance and weight reductions, while making additive manufacturing more affordable for production volumes.”

Several Desktop Metal customers are already benefiting from binder jetting titanium and aluminum. Robert Swenson, owner of TriTech, lauded binder jetting as a complement to their metal injection molding business, citing simplified production of complex geometries at lower costs. Additionally, significant projects are underway with major manufacturers using specialty materials developed by Kymera International, including titanium and aluminum.

Joe Croteau, Technology Manager at Kymera International, emphasized their collaboration with Desktop Metal in developing metal powder solutions optimized for binder jetting. With decades of metallurgical expertise, Kymera International has successfully printed a variety of aluminum geometries and part sizes, addressing the needs of high-volume manufacturers.

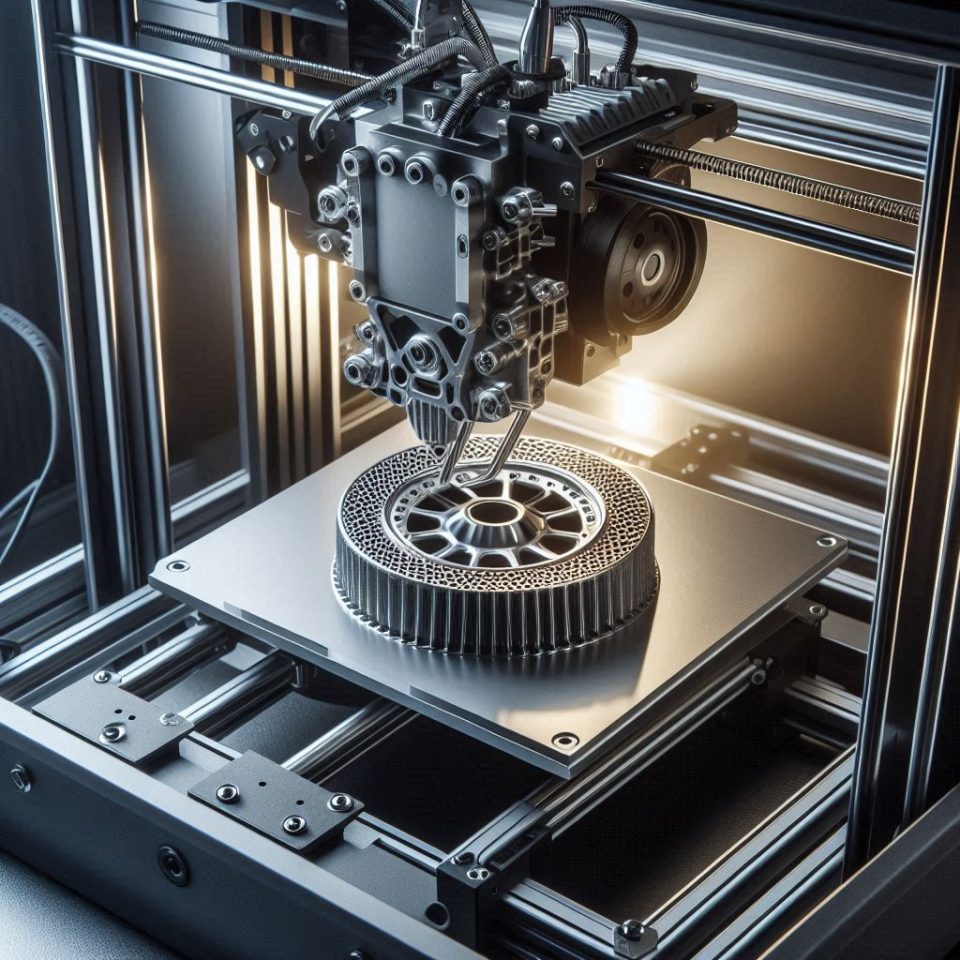

The Desktop Metal Production System P-1, along with titanium and aluminum designs, will be showcased at RAPID + TCT at the Los Angeles Convention Center. Binder Jetting, recognized as the fastest method of metal 3D printing for high-volume output, offers various benefits including size and weight reductions, part consolidation, and performance improvements. With more than 30 metals and ceramics qualified on Desktop Metal printers, the Production System P-1 is now capable of printing 17 metals, including stainless steels, copper alloys, nickel-based alloys, and more.

Today’s announcement elevates titanium to Customer-Qualified status on both the P-1 and X-Series models, while aluminum is now Customer-Qualified on the X-Series and R&D Qualified on the P-1, paving the way for expanded applications and innovations in the additive manufacturing industry.

Desktop Metal’s innovative Reactive Safety Kit signals a new era in high-speed binder jet 3D printing, positioning the company as a leader in additive manufacturing technologies for mass production.